ECO Plant

ECO Steel Plant

Hyundai Rotem has a major role in Hyundai Motor Group’s resource circulation business structure that connects molten iron to automobiles. Hyundai Rotem supplied various facilities for three phases of Hyundai Steel's Dangjin integrated steelworks including blast furances. In addition, Hyundai Rotem is leading the reduction of pollutant emissions in the steel industry with exhaust gas cleaning equipment and indoor coal storage facilities, and is fulfilling its responsibility.

Iron-Making Facility

Iron ore, coal and subsidiary materials are transferred and stored by sealed belt conveyors into the circular and linear storage facilities. The iron making facility produces sinter ore and coke out of these materials.

[Raw material handling facility] Facility that stores imported raw materials and transports them to each required process.

[Lime calcination facility] Facility that removes CO2 from limestone to calcine it and extract quicklime (CaO)

[Sintering facility] Facility that produces sintered ore by mixing fine iron ore with supplementary materials such as limestone and then heating them at high temperatures

[Coke-making facility] Facility that produces coke by carbonizing coal at high temperatures

Raw material handling facility

Lime calcination facilityy

Sintering facility

Coke dry quenching equipment

Blast Furnace

The blast furnace is a facility that produces molten iron by charging with iron ore, limestone, sintered ore and coke supplied from iron making facilities altogether through a combustion reaction using the hot air produced in the hot air furnace.

Hyundai Steel's blast furnace

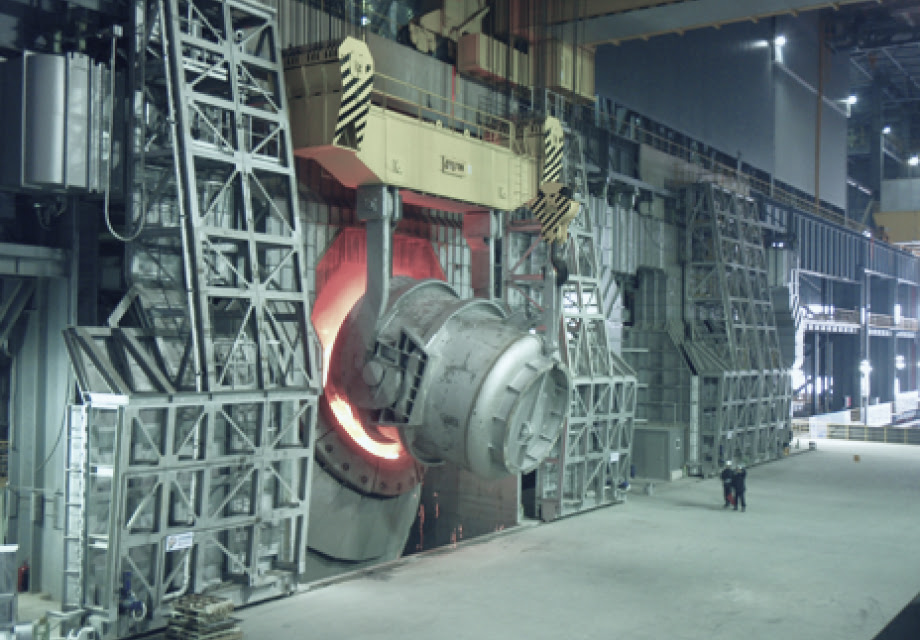

Steel-Making Facility

Steel making equipment produces slabs (semi-products) from molten steel which is produced through the process of removing impurities from molten iron and adjusting compositions suitable to the required steel type (specification).

[Hot metal pre treatment (Kanvara reactor)] Equipment that removes impurities such as silicon (Si), phosphorus (P), and sulfur (S) before charging molten iron into the converter

[Converter] Equipment that removes carbon (C) from molten iron through an oxidation reaction by adding oxygen

[LF refining equipment] Equipment that adjusts the temperature and composition of molten iron from the converter with arc heat (heat generated during electrical discharge)

[RH refining equipment] Equipment that removes gas (oxygen, hydrogen) and adjusts the composition of the solution through vacuum treatment

[Continuous Casting Machines] Equipment that continuously casts molten iron to produce slabs (semi products)

Kanvara reactor

Converter

Continuous Casting Machince

Ladle & Ladle Turret

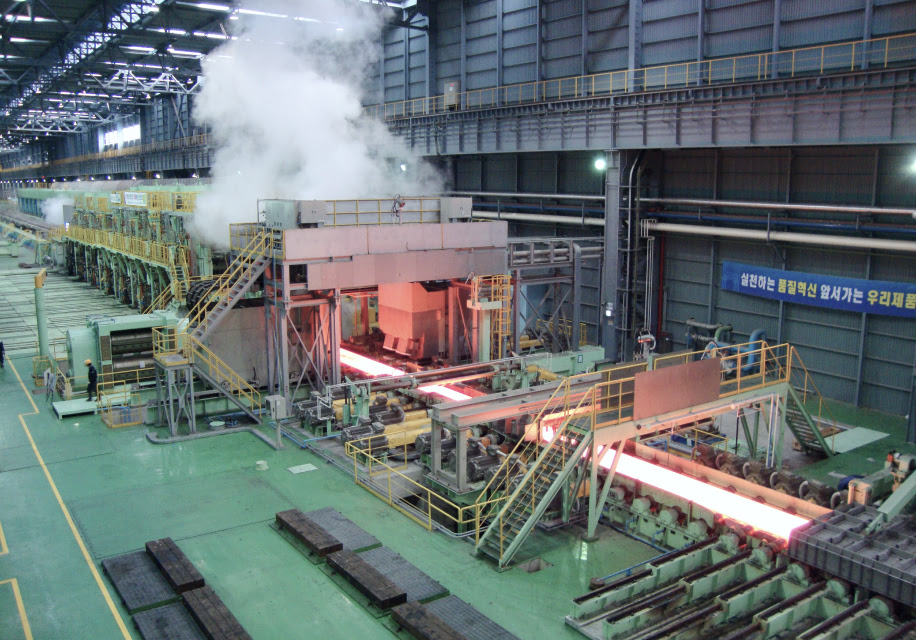

Rolling Mill Facility

Equipment that stretches or thins the slabs produced from in the continuous casting process with a continuous force applied by passing the slabs through several rotating rolls.

[Hot rolling mill facility] Facility that rolls slabs (semi products) to produce hot-rolled thick plates and steel plates of various specifications (thickness and length)

[Cold rolling mill facility] Facility that produces high-quality cold-rolled steel sheets with beautiful surfaces and excellent workability

Hot rolling mill

Cold rolling mill

ECO Environment and Supplementary Facility

[Environmental facility] Facility that purifies SOx and NOx contained in wastewater and flue gas that pollutes the environment. It converts the emitted carbon dioxide into recyclable

[Supplementary facilities] Facilities that produces oxygen, hydrogen and others necessary for the steelmaking process

Hyundai Steel Drainage Wastewater Treatment Plant

Hyundai Steel Sinter Exhaust Gas Cleaning Facility

Hyundai Steel Oxygen Faciltiy

Cranes

Hyundai Rotem is capable of suppling various equipment such as steelmaking ladles, cranes for transporting steel and steel plates, and cranes for port handling and offshore facility works.

Port handling equipment

Steelmaking crane